-

24 Jun 0

When considering using LED striplights (also known as “tapelights”) in lighting projects, one quickly realizes that there are many different products being offered in the market, with various qualities and technical characteristics. There are certain criteria that we can apply to help us determine what is the right type of striplight to use in any given situation. To prevent problems, consider the following 7 must-know TIPS:

#1. Line-Voltage vs. Low Voltage

The first consideration is what voltage to use (usually 120V, 12V, or 24V). This will depend on the application and other practical considerations for installation. Line-voltage (120V) striplights come in spools of 50 metres. This allows for installation of long stretches without the need to splice various sections, thus saving labor costs and time when installing. These tapelights can be cut every half metre (50cm).

On the other hand, most 12V and 24V striplights come in 5 metre spools. They are excellent options for use in boats, trailers, kitchens, and wet locations, including swimming pools and fountains, where low voltage is required for safety reasons. The cutting unit for most low voltage products is 5cm. They require a power adapter (DC12 V and DC 24V, respectively). It is critical to ensure that you use the right power adapter for the wattage and length of the striplight that you choose to employ.

#2. Length of striplight and number of LEDs per metre

Regardless of the brand to be used, LED striplights come in many different models, and the number of LEDs per metre vary. Usually, striplights come with 30, 60, or 90 LEDs per metre. There are some products featuring also 75, 120, and 144 LEDs per metre for certain special applications. Specialty striplights used as components for machinery and high-tech applications are also available.

Wide Loyal’s LED Striplight PRO (120V, 50m spool) has 60 high-output LEDs per metre. Each chip emmits an impressive 23 lumens, making it one of the brightest of its kind in the market.

Some manufacturers offer products containing 120 or 144 LEDs per metre, which are basically double strips. They generate a lot of heat, and are usually sold without a silicon sleeve or any other protection to prevent them from burning and to allow the heat to dissipate. Beware!

#3. Dust and Water Protection Grade

LEDs are sensitive to water and can be damaged by the action of ambient dust. There is a wide range of striplight protection grades. One recognized international guideline is the IP standard, which is comprised of two numbers: the first one denotes the water protection class, and the second one indicates the level of protection against dust:

| Type of Protection | Features | IP Grade |

| Unprotected | Plain striplight | 20 |

| Type A | Silicon Sleeve | 67 |

| Type B | Epoxy Coating | 68 |

| Type C | Silicon Sleeve and Epoxy Filling | 68 |

| Type D | PVC Tubing | Not recommended |

Type D is not recommended because the tubing turns yellow over time, and is easily damaged by chlorine, UV rays, and heat.

The protection grade is critical when comparing prices. Purchasers often overlook this feature, assuming that all products offer the same protection level.

#4. Lumens per linear metre generated

The striplight’s output is another crucial characteristic to take into account. The luminous efficacy is measured by the lumens produced per watt consumed by the striplight. This is determined by the quality of the LEDs (Wide Loyal uses high-end Epistar chips). The luminous efficacy is one of the most important points to look at when considering the use of any LED product.

The brightness of the striplight is a key factor also when considering installation behind crown moldings, trim pieces, light trays, etc. If the strip is to be exposed, bear in mind that each LED chip will be visible. For an “even”, neon-like effect, LED tubing such as Wide Loyal’s Flexi-Neon is recommended instead.

#5. LED Types

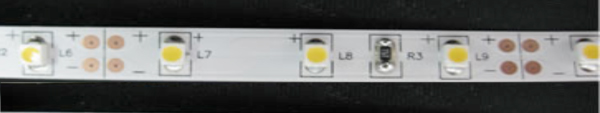

There are many types of LEDs used in various striplight models, including LED SMD 5060, LED SMD 5050, LED SMD 3528, LED SMD 335, and LED SMD 5730, among others.

The LED SMD (Light Emitting Diode Surface Mount Device) is, as the name indicates, an LED chip that is surface mounted on the striplight. The chip is enveloped in epoxy resin.

The SMD is a semi-conductor that can be either indium gallium nitride (emitting light in the green and blue part of the spectrum) or gallium phosphide (emits light in the red part of the spectrum). To produce white light, an LED emitter with a phosphor coating that emits at longer wavelengths is used, giving a full spectrum of visible light.

SMD technology offers many advantages. It is shock-resistant in normal application uses, it is also vibration-resistant, and does not emit either ultra violet or infrared light.

In addition, its color-rendering index (CRI) is greater than 85% in a scale ranging from 1 (very poor) to 100 (excellent). The CRI indicates how accurate a “given” light source is at rendering color when compared to a “reference” light source. The higher the CRI, the better the color rendering ability.

| LED Format | ||||

| SMD | 5060 | 5050 | 3528 | 335 |

| DIMENSIONS | 50*60 mm | 50*50 mm | 35*28 mm | 3*35 mm |

| TYPE | Monochrome | Monochrome | Monochrome | Monochrome |

| QUANTITY | 3 chips/LED | 3 chips/LED | 1 chip/LED | 1 chip/LED |

| CONSUMPTION | 0.30 Watts | 0.24 Watts | 0.08 Watts | 0.05 Watts |

| BEAM ANGLE | 120 Degrees | 120 Degrees | 120 Degrees | Side-Emitting |

SMD 35*28

SMD 50*50

SMD 3*35

#6. Power supplies, controllers, and other accessories

In addition to line-voltage striplights, these products are available for use with 12V or 24V power adapters fed from 105/230 Volt networks, usually AC.

It is important to know the watts that each strips consumes to be able to determine if the power supply can provide the necessary power without any problems. Most striplights are dimmable using an LED dimmer.

Wide Loyal’s striplights are supported by a complete line of accessories, including mounting channels and clips, end caps, various types of splice connectors, power cords, light dimmers, and controllers, etc.

The company provides the only power cord/rectifier capable of safely loading up to 600ft (200m) of striplight. This prevents one of the most common problems encountered in striplight installations: overheating and power cord failure – which may lead to fire hazard.

#7. Some Mounting Recommendations

> Do not connect the striplight to the power supply with the power on.

> Follow the striplight’s polarity; positive to power supply positive.

> Ensure that the power source is adequate for the striplight.

> Ensure that the striplight, the power supply, and all connections are properly protected as per the job requirements.

> Ensure that no elements that may damage the striplight are in its proximity, such as heaters or abrasive materials.

- Ensure that the heat generated by the striplight can be dissipated effectively.

- Do not light up the striplight unless the spool is unrolled. Ligting it up unrolled will overheat the materials.

| LED TYPE | SMD 3528 | SMD 3528 | SMD 5050 | SMD 5050 |

| LEDs/m | 60 | 120 | 30 | 60 |

| CONSUMPTION (W/m) | 4.8 | 10 | 7.5 | 14.5 |

| VOLTAGE | 12 VDC | 12 VDC | 12 VDC | 12 VDC |

| AMPs | 2 | 2 | 6 | 6 |

| LUMENS/m | 220/360 | 440/720 | 360 | 720 |

Millicandelas (LED mcd)* according to LED type and color:

| LED TYPE SMD3528 | BRIGHTNESS (MILLICANDELAS) | LED TYPE SMD5050 | BRIGHTNESS (MILLICANDELAS) |

| RED | 1000-1200 MCD/LED | RED | 3000-4000 MCD/LED |

| YELLOW | 1000-1200 MCD/LED | YELLOW | 3000-4000 MCD/LED |

| BLUE | 400-600 MCD/LED | BLUE | 2500-3500 MCD/LED |

| GREEN | 1500-2000 MCD/LED | GREEN | 4000-5000 MCD/LED |

| WHITE | 1600-2000 MCD/LED | WHITE | 4000-5000 MCD/LED |

| WARM WHITE | 1600-2000 MCD/LED | WARM WHITE | 4000-5000 MCD/LED |

| RGB | NO | RGB | 2500-3500 MCD/LED |

*Milicandela (LED mcd) is another method used to specify the intensity of the light emitted.

Finally, it is advisable to bear in mind that not all striplights are made equal. Wide Loyal’s PRO series, for example, is manufactured with pure copper wiring – no aluminum – which offers greater durability and reliability. The PRO striplights are also protected with a double anti-corrosion coating (on both sides of the strip), and high-quality PVC. These features, while not obvious to the naked eye, can make the difference between a successful application and unnecessary headaches down the road.

For QUOTES and more information about buying LED Striplights of any color and size please contact us now by calling us toll FREE Monday to Friday 7:00am to 4:00pm Pacific Standard Time at: 1 (888) 303-0931 or send us a message through our CONTACT FORM HERE!

Wide Loyal Team

Leave A Comment

You must be logged in to post a comment.